RELIABLE AND COMPACT POWER GENERATION SYSTEMSINDUSTRIAL POWER GENERATION

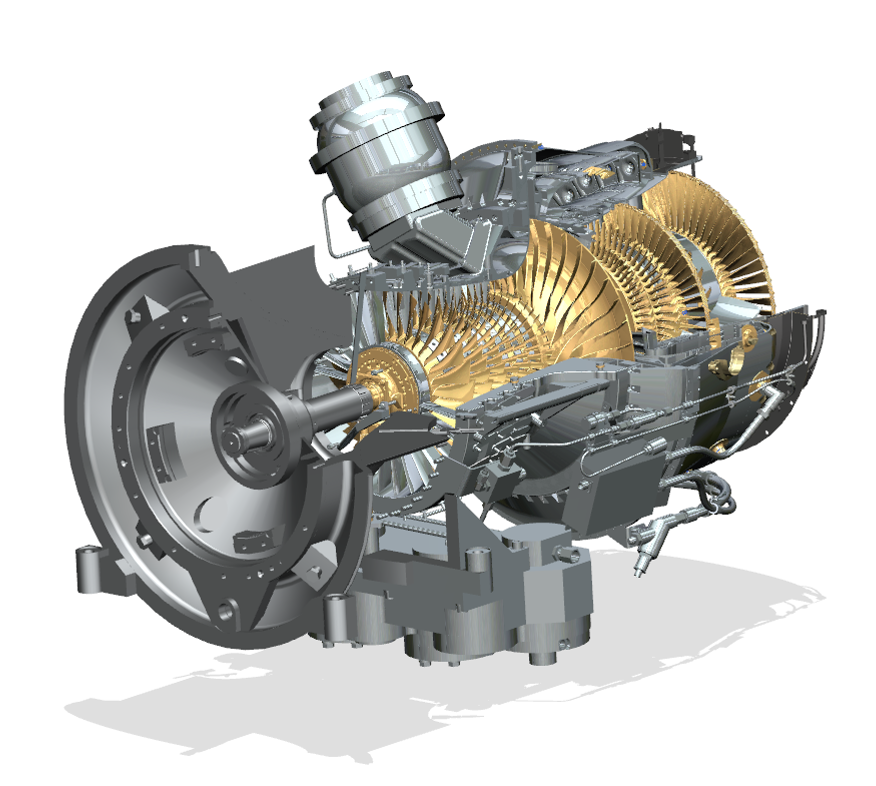

Vericor's aero-derivative gas turbine solutions are high power density. They generate a large amount of power in a compact, light-weight footprint allowing for installation in locations where space is limited. These units can be started and stopped as needed without reduction in life allowing users the flexibility to easily meet varying power requirements.

SPACE AND COST EFFICIENCY

With over twenty years of service, Vericor’s products have earned a reputation for reliability and durability. Vericor packages can be customized to fit your specific application. The compact size, flexible design and best-in-class service make it easy to see why Vericor products are sought after for power generation applications. All packages are factory-tested prior to shipment to prove system quality, integrity and performance.

STATIONARY POWER

Vericor power generation packages offer the smallest footprint in their power class and can easily integrated into your new or existing facility. We deliver a generator set that is ready for easy installation, fast commissioning and reliable operation lowering your overall project costs.

MOBILE POWER

Vericor mobile power generation packages offer the smallest footprint and lowest weight in a single trailer design and can be easily transported to remote locations. Our fully integrated single trailer design can be set up in a short amount of time with minimum on-site labor.

HIGHLIGHTS

- Packaged power generation solutions available

- Highest installed power-to-weight ratio in its class

- Cold-end drive, close coupled configuration with axial exhaust

- Modular gas turbine simplifies service and minimizes downtime

- Minimal alignment required after set up or engine exchange

- High reliability and availability

- Fast start and load capability

- Flexibility to burn gaseous or liquid fuels

APPLICATIONS

- Simple Cycle Power

- Combined Heat & Power

- Remote Power

- Mobile Power

Interested In More Information?

STAY CONNECTED