SUCCESS STORYMobile Compression: Gas turbine provides effective means to evacuate natural gas pipeline

Recover up to 80% of natural gas in pipeline without venting or maintenance.More About Vericor's ASE40B

The Challenge

Recover up to 80% of natural gas in pipeline section without venting

Vericor's Solution

Connect a 3MW or 3.5MW Gas Turbine Compressor to evacuate and bypass the fuel around a maintenance location

The Results

Over 15 years of reliable pulldown operation with follow-on order

Overview

The Vericor ASE40 has been deployed for over 35 years in a mobile pull- down compressor trailer owned and operated by a major North American pipeline company and a world leader in the use of mobile compressor technology for natural gas pipeline maintenance.

The ASE40 engine is direct mounted to and cantilevered from a centrifugal compressor on a single drop down heavy duty trailer and housed in a sound attenuated enclosure with a full cast of auxiliary support systems. This mobile trailer is capable of accessing natural gas pipelines in remote areas and in the harshest climates. The trailer is utilized across multiple stations throughout Canada and the United States as a means to evacuate gas out of pipeline segments that are scheduled for maintenance.

The pulldown trailer helps save approximately 70-80 per cent of the pipeline natural gas that otherwise would be released to the atmosphere. Due to its long term success of the initial trailer design, an additional trailer will be added to the fleet using Vericor’s latest industrial turbine, the ASE50B.

The ASE50B provides the next generation of mobile compressor trailers an additional 20% capability in performance over ASE40 and higher torque capability to maximize performance.

The ASE40 engine is direct mounted to and cantilevered from a centrifugal compressor on a single drop down heavy duty trailer and housed in a sound attenuated enclosure with a full cast of auxiliary support systems. This mobile trailer is capable of accessing natural gas pipelines in remote areas and in the harshest climates. The trailer is utilized across multiple stations throughout Canada and the United States as a means to evacuate gas out of pipeline segments that are scheduled for maintenance.

The pulldown trailer helps save approximately 70-80 per cent of the pipeline natural gas that otherwise would be released to the atmosphere. Due to its long term success of the initial trailer design, an additional trailer will be added to the fleet using Vericor’s latest industrial turbine, the ASE50B.

The ASE50B provides the next generation of mobile compressor trailers an additional 20% capability in performance over ASE40 and higher torque capability to maximize performance.

Product Spotlight

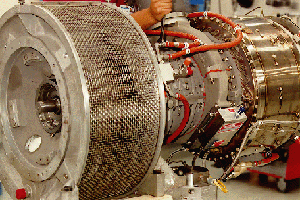

ASE40B

The Vericor ASE40B aero-derivative industrial gas turbine is used for power generation and mechanical drive applications across a range of industries such as oil & gas, industrial, commercial and institutional.