Story Issued & Highlighted In Gas Compression Magazine | Jan 2021

ATLAS COPCO GAS AND PROCESS PARTNERS WITH VERICOR POWER SYSTEMS TO UTILIZE GAS TURBINES TO POWER INTEGRALLY GEARED CENTRIFUGAL COMPRESSORS.

Written by Daniel Foelber

Atlas Copco Gas and Process (Atlas Copco) and Vericor Power Systems (Vericor) have entered into an agreement that will use Vericor's gas-driven turbines to power Atlas Copco's integrally geared centrifugal compressors. Both companies believe the partnership will drive sales and reduce costs while giving customers a reliable and cost-effective compression solution. "Customers in the gas processing compression market require reliable power to drive compressors in remote applications. Atlas Copco Gas and Process manufactures long-running integrally geared compressors and needed a partner to provide a power solution that is as reliable as their compressors. Vericor's gas-driven turbines offer consistent and cost-effective power with extended maintenance intervals, making them the perfect choice to power these compressors,” said Vericor CMO and Vice President of Oil and Gas Umberto Marseglia.

A NEW MARKET FOR VERICOR

Before the partnership with Atlas Copco, Vericor had a minor presence in the gas compression market. Most of Vericor's business involves being an original equipment manufacturer (OEM) that sells and supports aeroderivative gas turbines for marine propulsion; mechanical drive and power generation applications, including high-speed military and civilian ships; industrial pumping; compressor or electric generation applications; and oil field applications. The company believes its new solution can open the door to previously untapped markets around the world.

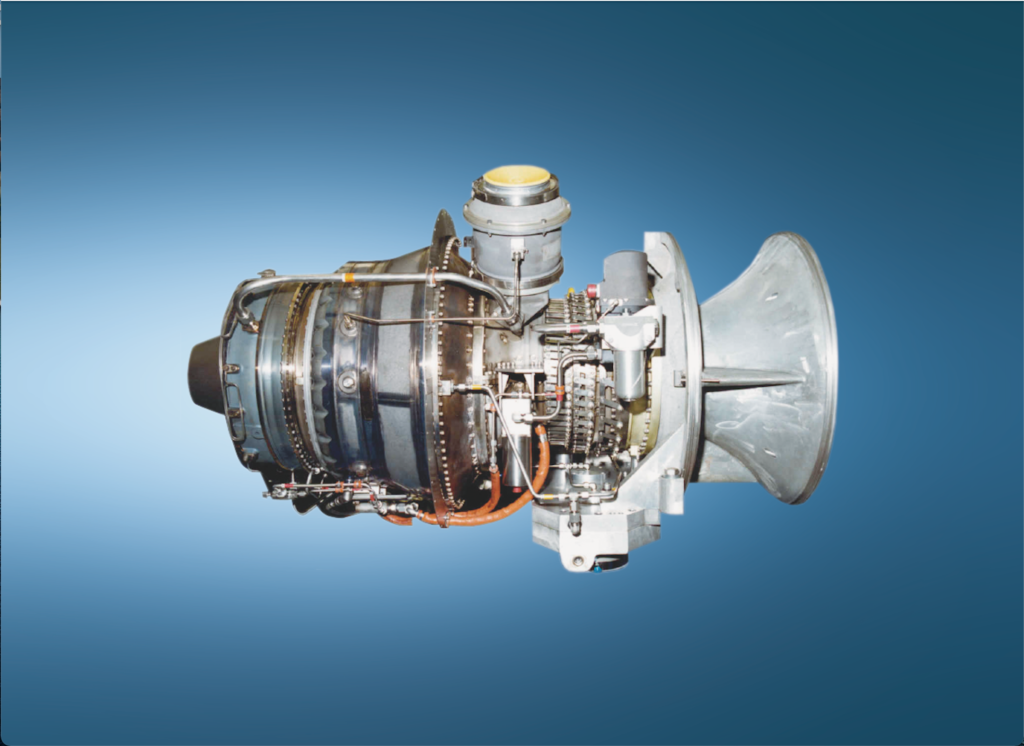

Known as a compander, which is a compressor and radial turbo expander mounted on the same gearbox, the GT-series compressor from Atlas Copco and the 5000-hp (3728-KW) dual-shaft ASE50B gas turbine from Vericor are expected to complement each other by shortening installation times, lowering capital expenditures, and saving on energy costs. Although this specific com pander combination is the only option available at this time, both companies could explore other product combinations as the alliance progresses.

BENEFITS OF THE PACKAGE

The ASE50B gas turbine was specifically chosen for the compander pairing for its flexibility and adaptability. With a length of 64 in. (1.63 m) and a weight of close to 1400 lb. (635 kg), the gas turbine keeps the weight of the overall compressor package low. According to Vericor, the ASE50B is compact, light, reliable in the most challenging environments, and flexible in terms of fuel adaptability.

Marseglia notes that the benefits of a gas turbine-powered compressor and compander will depend on the comparison. “Considering a comparison with a diesel engine, the gas turbine offers the benefits of much lower maintenance cost, lower weight, higher reliability, lower emissions, environmental friendliness including lower noise levels, and excel lent cold start capabilities (mainly in the case of the Vericor gas turbine). Compared with an electrical motor that is generally driven by a gas turbine, the benefit of having the gas turbine directly (mechanically) coupled with the compressor is the reduction in the equipment needed (transformer, variable speed drives [VSDs], electrical cables, switches, etc.). There's also a direct and substantial reduction in capital expenditures and complexity, a reduction in operating expenditures, and an increase in transportability and operability, which is critical in remote areas where this equipment is generally used,” said Marseglia.

Both companies believe their new solution can compete in rugged environments where “few other packages could survive.” “Both Atlas Copco compressors and Vericor turbines are built for robust, reliable operations. Atlas Copco compressors and companders offer 99.8% reliability and 99.7% availability. This is coupled with a design that can run continuously for five years with only minor, non-shutdown maintenance required. The Vericor turbine has roots in the defense industry, where reliability is paramount. The ASE50B can run nonstop for three or more years, apart from low-level maintenance, allowing the customer to operate the compressor/turbine package with little to no man power,” said Marseglia.

A GLOBAL INITIATIVE

The combined reach of Atlas Copco and Vericor's marketing and supply chain networks gives the compressor package a virtually unlimited total addressable market. “The strategic alliance is intended to be worldwide but is limited to those areas as imposed by US trade control and compliance and faces commercial limitation in areas where the companies do not feel it is appropriate or convenient to operate. Globally, there are several markets where we see potential. We are prioritizing market selection based on multiple risk opportunity profiles to examine which areas make the most sense for both companies. The total addressable market varies depending if we consider solely new markets or technology replacement as well. The replacement could be diesel engine power production and/or electrical motor combinations,” said Marseglia.

EVERY DOLLAR COUNTS

2020 hasn't been particularly kind to the energy industry. Bankruptcy firm Haynes and Boone reports that the cumulative debt of US exploration and production (E&P) companies is now at its highest level since the firm began tracking the data in 2015. Forty bankruptcies were recorded in the first three quarters of 2020, nearly as many as in all of 2019 and significantly more than the 28 reported in 2018 or the 24 bankruptcies in 2017. As of October 31, 2020, energy was the worst performing sector in the US stock market, losing over half its value in 2020 compared to the market's 1% gain.

Insulated by strong demand from power generation, industrial processes, residential users, and a growing liquefied natural gas (LNG) and compressed natural gas (CNG) market, natural gas-related businesses have been perform ing significantly better than their oil-specific peers. In fact, the US Energy Information Administration (EIA) estimates that natural gas prices could be 50% higher in 2021 com pared to 2020, driven by rebounding domestic and global demand and lower overall supply:

(see "Mergers & Markets:50% Higher Natural Gas Prices In 2021,” October 2020 Gas Compression Magazine, p. 6).

Vericor's decision to expand its footprint in the gas compression industry during a relatively difficult business cycle stems from the company's belief that its product can meet the needs of its customers' operations while reducing costs. In this way, Vericor and Atlas Copco customers could better compete in a time where every dollar counts.

“As a relatively new package, some engineering challenges occurred during the initial development phase. However, these have been identified and addressed in the current product configuration,” said Marseglia. “I do believe that the total cost of ownership (TCO) is one of the major challenges for the gas compression industry, where the TCO is a complex result of simple elements that include direct and indirect costs in a market that is extremely competitive. Some of the key TCO components are operation safety, environmental friendliness, cost of equipment and maintenance, frequency of maintenance and required downtime, remote monitoring and troubleshooting capabilities, personnel skills required to operate, and many others.”

"I do believe that the multiple added efficiencies of this package and the reliability and ease of maintenance of the package can provide significant savings to the user over the life of the machine and greatly support the TCO proposition,” continued Marseglia. “Vericor gas turbine is a simple engine and extremely reliable, with very low maintenance needs that can be remote-monitored for predictive maintenance and easy troubleshooting, covering the needs of a package of these characteristics.”

THE NEXT 20 YEARS

Vericor marks its 20th anniversary. Opening its doors in Alpharetta, Georgia, in January 2020, Vericor President and CEO Richard Clinton made it a point that the company plans to stay diligent. “In 2020, let's be purposeful. We have a lot to accomplish. As a company, we have to drive our business with passion and energy. We have to prioritize and do only what is most important for us to be successful with a laser focus. Don't take the easier path. Live life with passion and give it everything you have because you only get one shot at it,” said Clinton.

In many ways, the company's recent partnership with Atlas Copco embodies the spirit of Clinton's January message. On the package specifically, Marseglia commented, “The main goal, as always, is a happy customer and to expand our branding and Vericor's presence in the gas compression market. This strategic alliance allows us to be more competitive in the gas compression market by aligning ourselves with a company with the reputation of Atlas Copco.”

In its first 20 years, Vericor installed more than 1000 gas turbines worldwide and logged over 15 million hours of field experience. “We have very talented people who have a passion for solving customer problems, and our company has an entrepreneurial spirit that is really exciting to be a part of,” said Clinton. Over the next 20 years, the company hopes to expand its product portfolio, offering more customers its components and services at a fair value.