SUCCESS STORYGas Turbine driven Gas Compressor provides decades of reliable power source

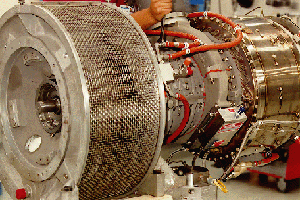

Vericor’s ASE40 Gas Turbine provides 3.0MW of compressor power in a continuous duty application.More About Vericor's ASE40B

The Challenge

Provide continuous duty, reliable power to gas compressor application

Vericor's Solution

Install Vericor’s ASE40 Gas Turbine directly to compressor drive

The Result

High power compression capable of operating reliably with high availability

Overview

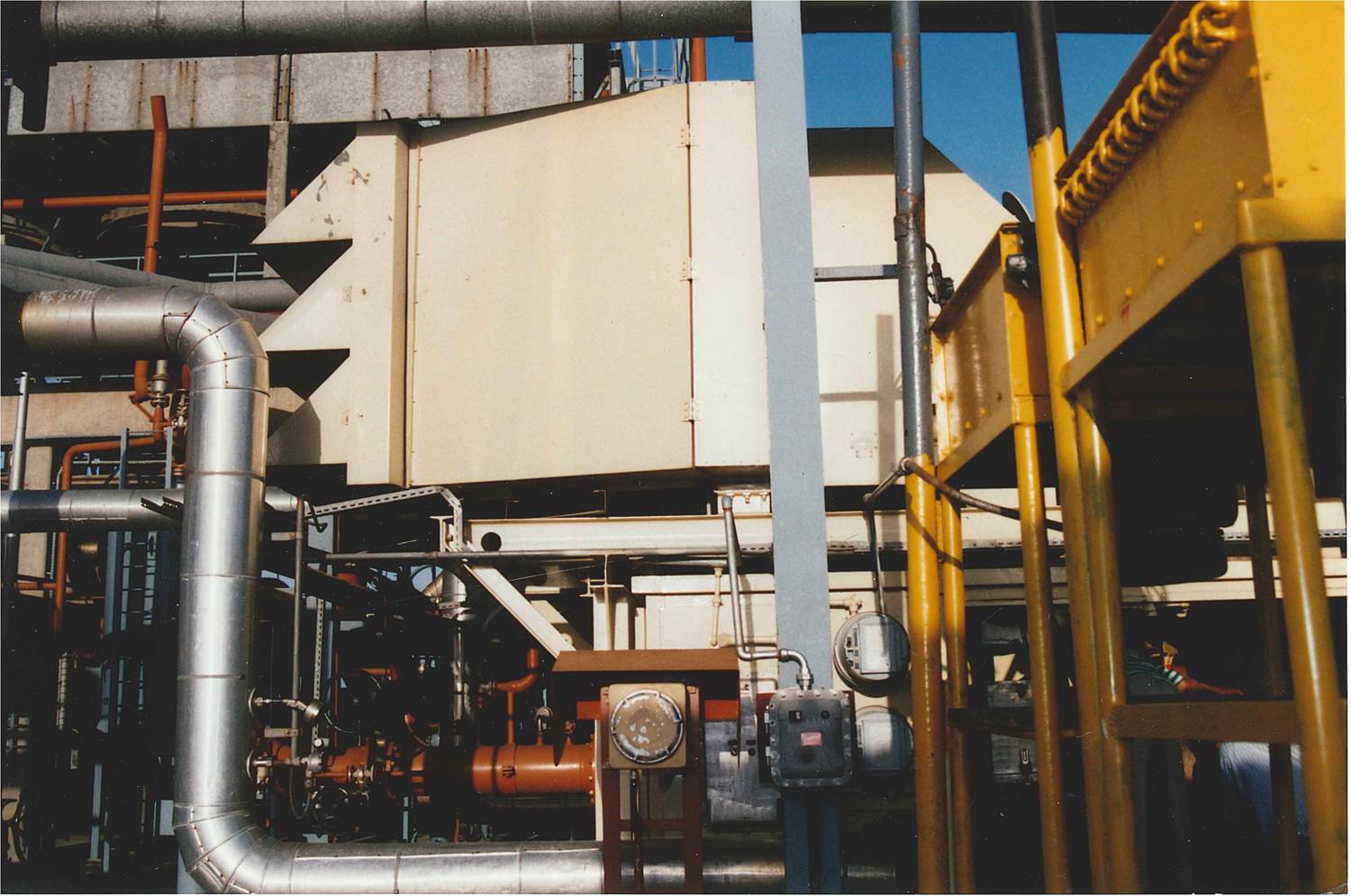

As the first industrial end-user of the ASE series aero-derivative gas turbine, Pakistan Oilfields has been operating two ASE40 engines on a continuous duty compressor drive application since 1979. Their successful natural gas gathering operation has logged over 500,000 hours of operation with minimal down time.

Vericor’s versatile ASE40 and ASE50B engines are highly suitable for compressor drive applications in either stationary or mobile packages. Both engines are fitted with a radial inlet, a rugged accessory gearbox for continuous duty operation, and gas starter for starting off readily available pipeline gas. The stationary applications are currently used for gas processing facilities in Pakistan and Japan, with hundreds of thousands of hours of operation. The mobile compressor package has been successful for pipeline pump-down applications in Canada. With the small footprint, lightweight engine and mobile characteristics, the mobile compressor package can be moved to strategic points along a pipeline where maintenance is most needed.

The versatile mobile compressor package is still in demand today as the ASE40 is being applied to meet greater compression demands.

Vericor’s versatile ASE40 and ASE50B engines are highly suitable for compressor drive applications in either stationary or mobile packages. Both engines are fitted with a radial inlet, a rugged accessory gearbox for continuous duty operation, and gas starter for starting off readily available pipeline gas. The stationary applications are currently used for gas processing facilities in Pakistan and Japan, with hundreds of thousands of hours of operation. The mobile compressor package has been successful for pipeline pump-down applications in Canada. With the small footprint, lightweight engine and mobile characteristics, the mobile compressor package can be moved to strategic points along a pipeline where maintenance is most needed.

The versatile mobile compressor package is still in demand today as the ASE40 is being applied to meet greater compression demands.

Product Spotlight

ASe40B

INDUSTRIAL GAS TURBINE

The Vericor ASE40B aero-derivative industrial gas turbine is used for power generation and mechanical drive applications across a range of industries such as oil & gas, industrial, commercial and institutional.