Success StoryGas Turbines Provide Highly Reliable Heat & Power To Office High Rises

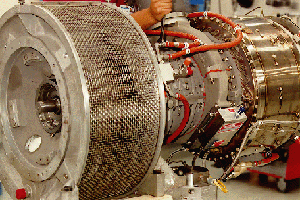

Dual Fuel capability of the Vericor ASE40 Gas Turbine ensures customer is never without critical power and utility supplyMore About Vericor's ASE40B

The Challenge

Provide daily Start-Stop power, steam, chilled water and hot water for multi- building complex in urban setting

Vericor's Solution

Install two Vericor ASE40 Gas Turbines in cogeneration with a heat recovery system and absorption chiller

The Result

Co-generation plant with Vericor gas turbine has logged over 50,000 hours over 10 years with an equivalent energy cost that is a fraction compared to grid and other utilities

Overveiw

Several modern office buildings are developed in the Shinagawa area of Tokyo, Japan. Hidden in the basement of one particular complex is a state- of-the-art cogeneration system that supplies multiple buildings with up to 5.2MW of electrical power and 16,000 kg/hr of 8.5 bar(g) saturated steam to feed an absorption chiller that produces chilled and hot water.

Vericor’s packager in Japan installed three of their own ASE40 Gas Turbine Generator Sets. Two of the gensets employ cogeneration steam systems with dual fuel capability for natural gas and A-Heavy oil, and one genset is a standby unit fueled by A-Heavy oil only.

The two cogeneration plants operate on a daily start-stop schedule to provide power and heat during business hours and shut down overnight.

The ASE40 engines are capable of starting from stop to full load in less than a few minutes and can switch fuels on the fly, giving remarkable flexibility to the operators to mitigate unknown power and fuel outages in this critical application.

Vericor’s packager in Japan installed three of their own ASE40 Gas Turbine Generator Sets. Two of the gensets employ cogeneration steam systems with dual fuel capability for natural gas and A-Heavy oil, and one genset is a standby unit fueled by A-Heavy oil only.

The two cogeneration plants operate on a daily start-stop schedule to provide power and heat during business hours and shut down overnight.

The ASE40 engines are capable of starting from stop to full load in less than a few minutes and can switch fuels on the fly, giving remarkable flexibility to the operators to mitigate unknown power and fuel outages in this critical application.

Product Spotlight

ASE40B

Industrial Gas Turbine

The Vericor ASE40B aero-derivative industrial gas turbine is used for power generation and mechanical drive applications across a range of industries such as oil & gas, industrial, commercial and institutional.