SUCCESS STORYHydraulic Fracturing: Gas turbine proves successful in shale gas field operations

Gas turbine drives a 4500 hhp pump to provide high flow and pressure in hydraulic fracturing application.More About Vericor's TF50F

The Challenge

Provide sufficient power on a single trailer to drive a 4500 hhp pump using wellhead gas

Vericor's Solution

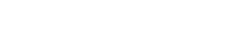

Install a Vericor TF50F gas turbine, with dual fuel capability, to a reciprocating pump on a truck

The Results

- Reduced fleet size and footprint with highly reliable turbine power

- High torque output at low rpm with real- time torque monitoring

- Dual fuel switching while under load

Overview

In May 2015, a new design for a turbine fracturing pumper, the Apollo 1, made successful tests in the shale gas well zipper fracturing operation by CNPC in Weiyuan County, Chinese Sichuan province in China. Under a wellhead pressure of up to 75MPa, the unit delivered a steady performance at 2.2m3/min displacement, which is nearlt equivalent to the output displacement of two conventional 2500hhp drivetrains.

By June 2015, Apollo 1made its appearance in the operation of CNPC Zhejiang oilfield in Chinese Sichuan Province where three layers were fractured each day. Each job takes 3.5 hours and 15 layers in total. The following month, the unit joined the operation by SWMS, a J.V company of CNPC and Shell, in Longhui county, Weiyuan city, Sichuan province and succeeded in fracturing 23 layers.

The Apollo 1’s high power of 4500hhp pump is highly applicable to high pressure well conditions and challenging operations that demand significant displacement volumes at reduced operating costs. The presence of several conventional units will make the whole job more flexible and efficient.

As the output flow rate of a single turbine fracturing pumper equals those of two conventional 2300hhp combined, the footprint of fleet, pipe connecting workload and crew members are nearly halved compared to conventional operations.

By June 2015, Apollo 1made its appearance in the operation of CNPC Zhejiang oilfield in Chinese Sichuan Province where three layers were fractured each day. Each job takes 3.5 hours and 15 layers in total. The following month, the unit joined the operation by SWMS, a J.V company of CNPC and Shell, in Longhui county, Weiyuan city, Sichuan province and succeeded in fracturing 23 layers.

The Apollo 1’s high power of 4500hhp pump is highly applicable to high pressure well conditions and challenging operations that demand significant displacement volumes at reduced operating costs. The presence of several conventional units will make the whole job more flexible and efficient.

As the output flow rate of a single turbine fracturing pumper equals those of two conventional 2300hhp combined, the footprint of fleet, pipe connecting workload and crew members are nearly halved compared to conventional operations.

Product Spotlight

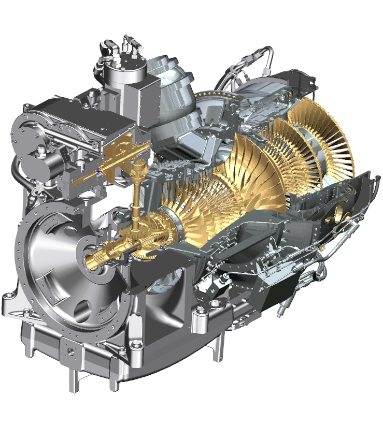

TF50F

INDUSTRIAL GAS TURBINE

The Vericor TF50F aero-derivative industrial gas turbine, with the highest power to weight ratio in this power class is used for mobile or portable mechanical drive applications including hydraulic fracturing and gas compression.